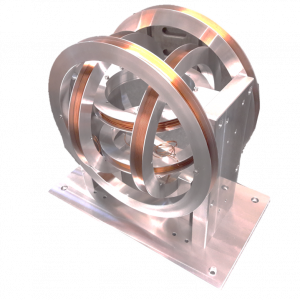

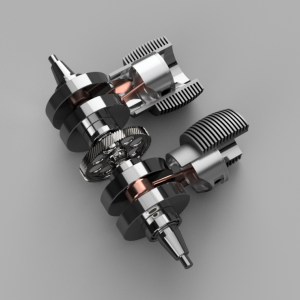

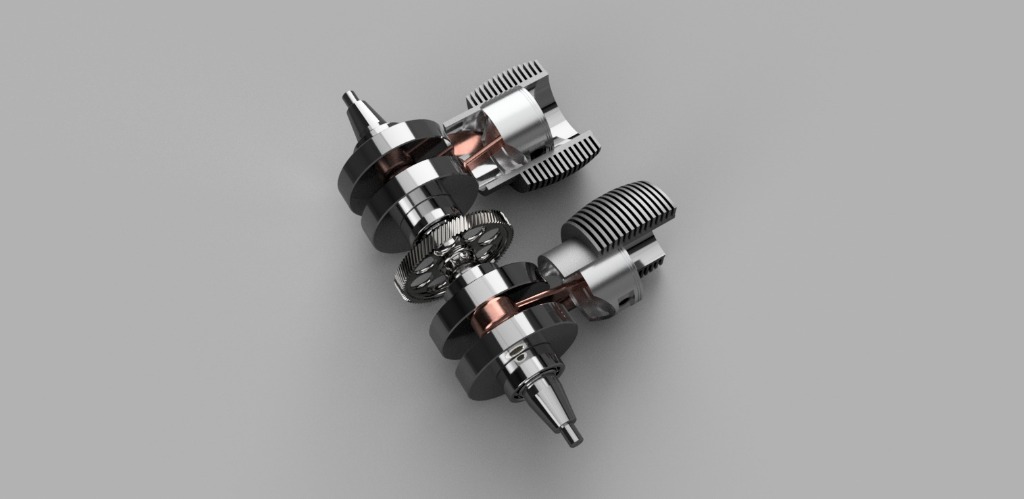

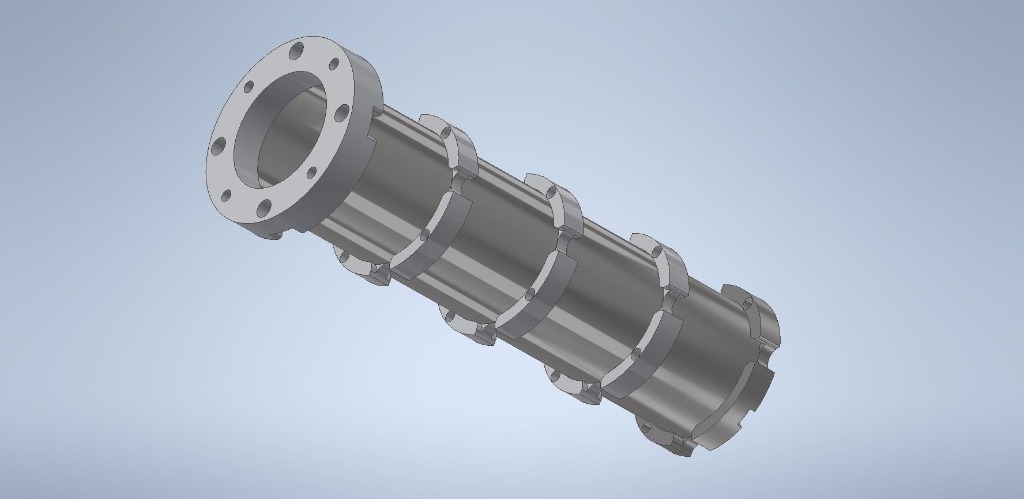

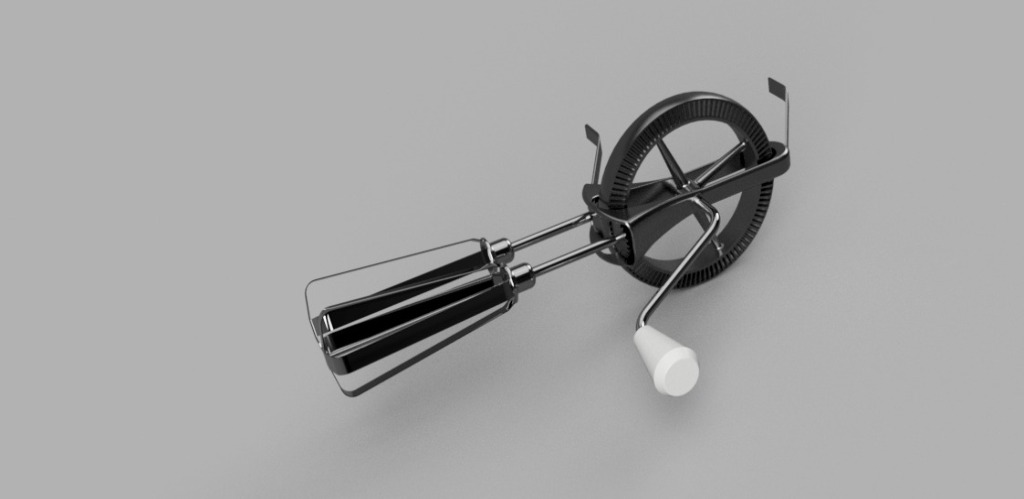

Turn your idea from concept into reality, full design service offered starting from concept to producing fully working CAD models.

We can work from a blank canvass, 2D sketches and drawings and produce digital engineering drawings; models; animations and videos.

Early consultation allows any design or manufacturing tips to be implemented, sometimes subtle design changes makes the difference whether a design works or not, changes can also influence the manufacturing efficiency.

We are happy to discuss your ideas and offer advice on:

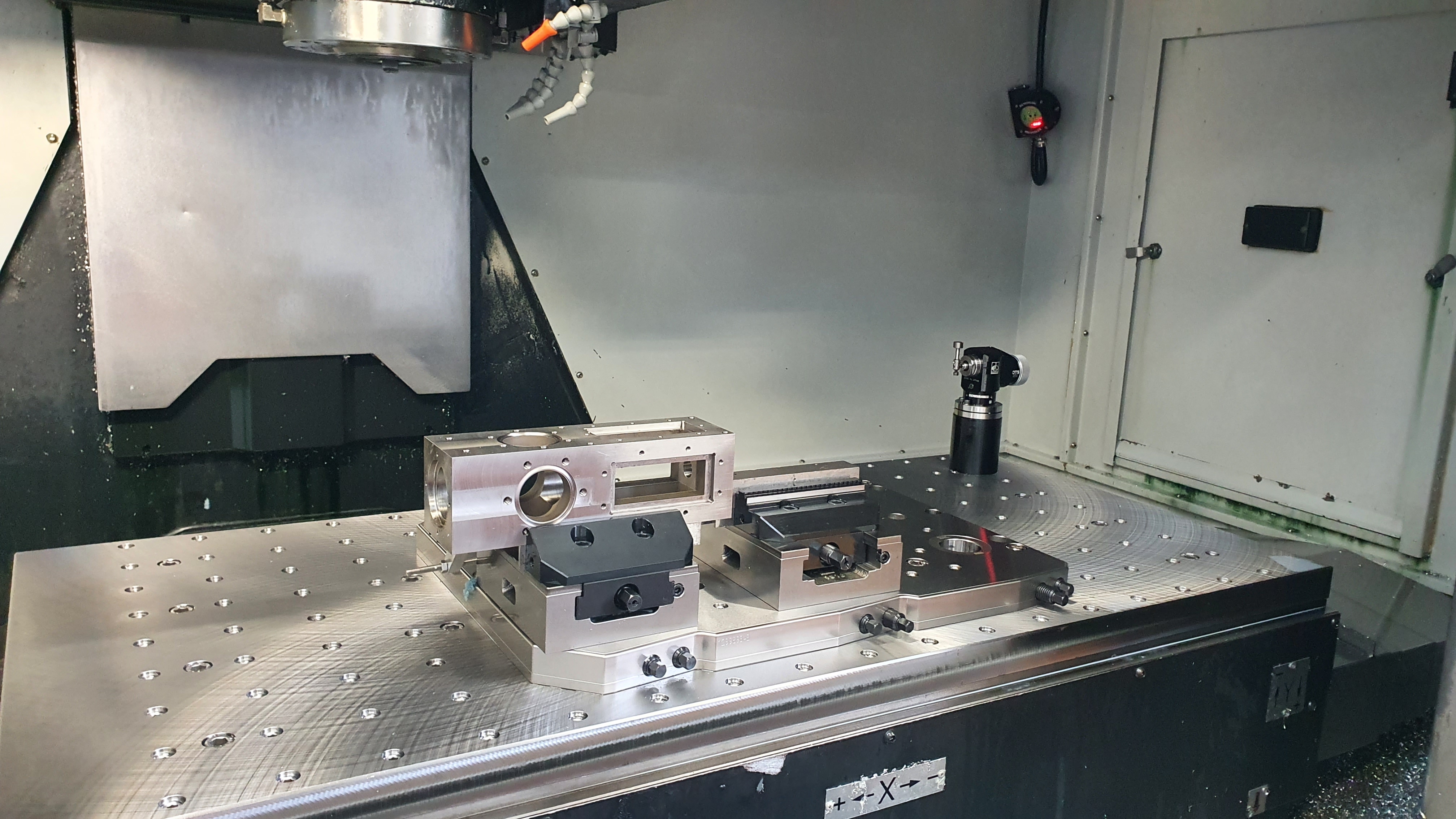

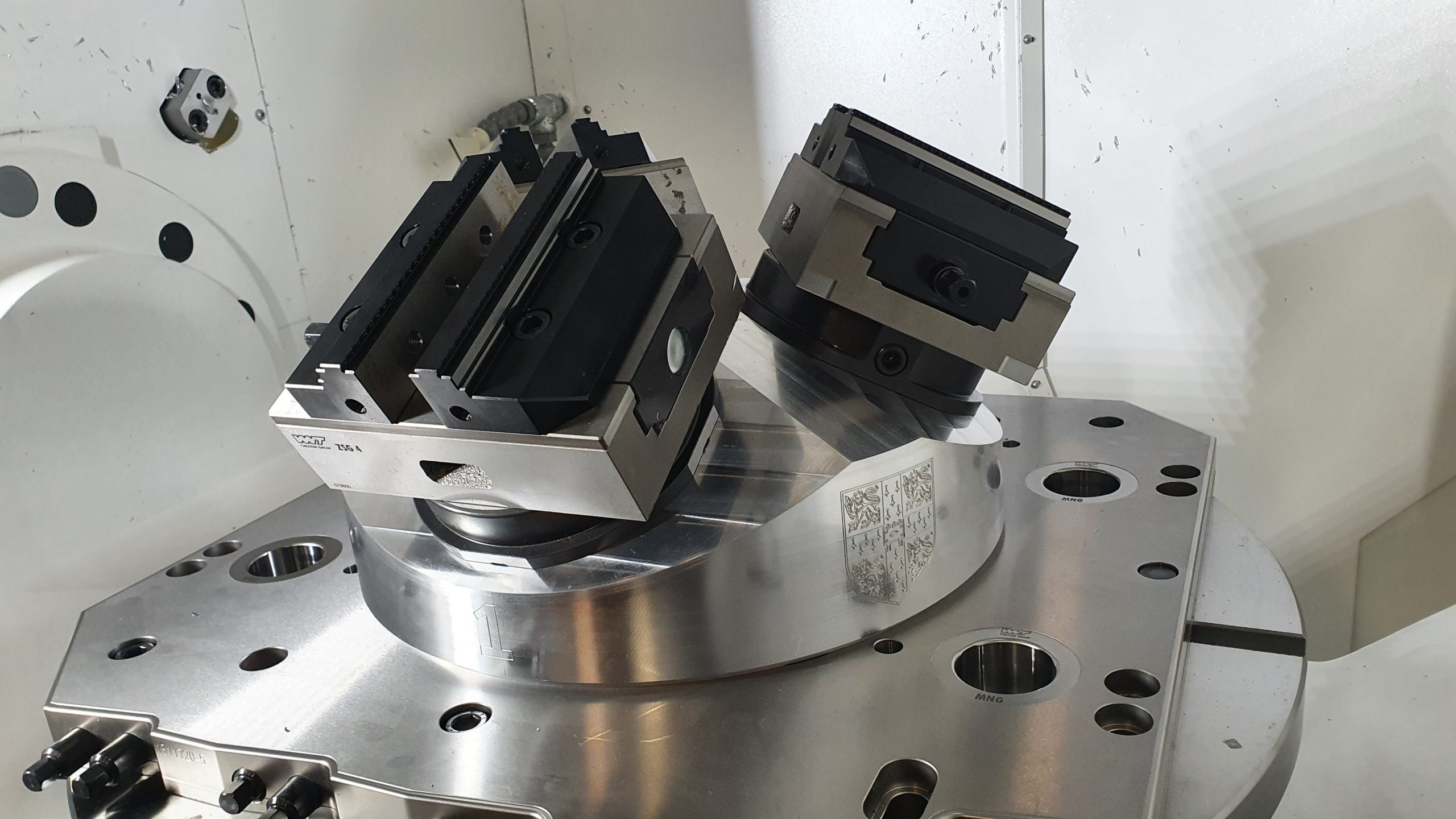

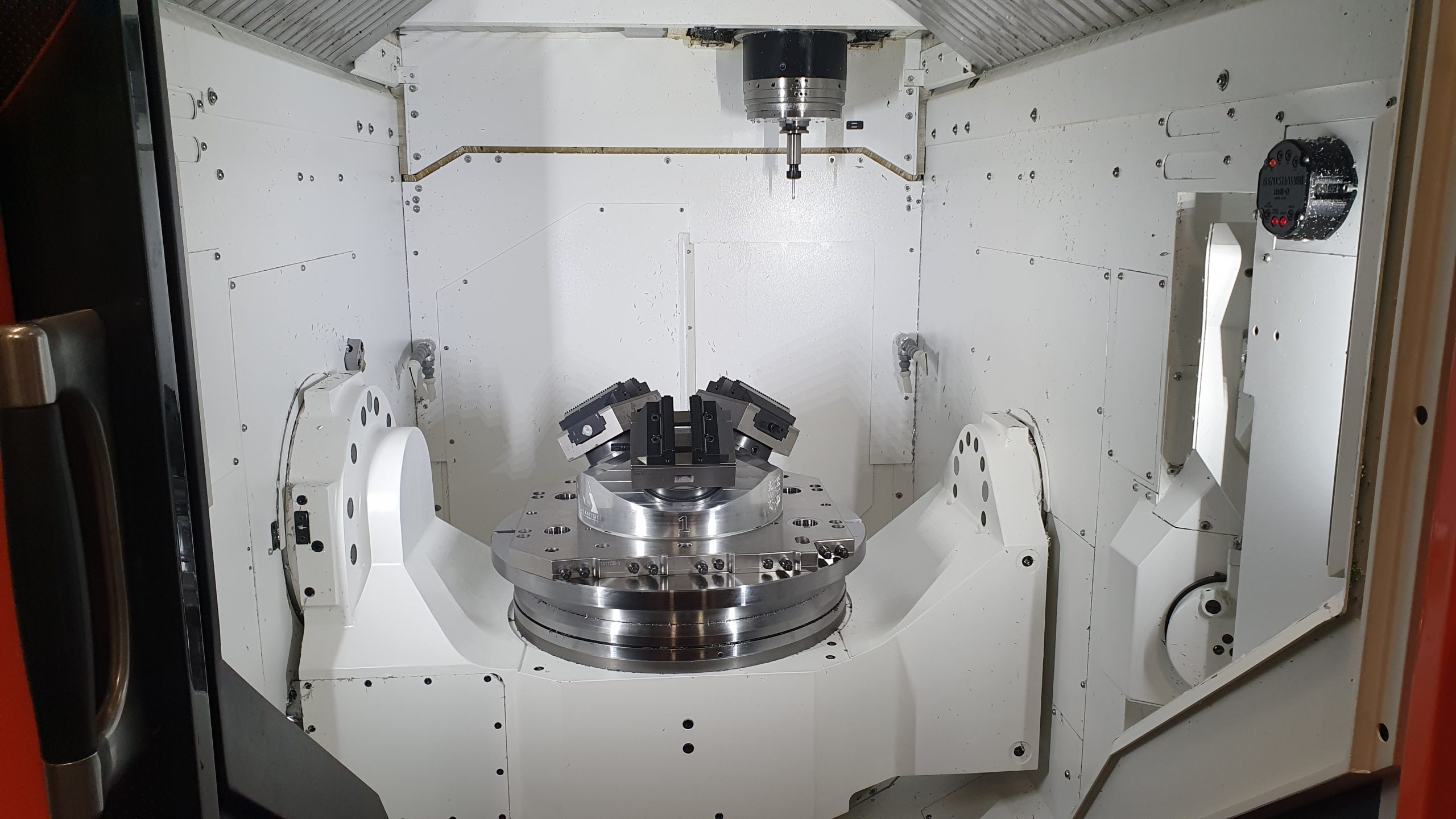

- Manufacturing techniques and tolerances including our in house CNC machining; EDM & 3D printing.

- Materials types & sizes, tolerances; from both industry standards and knowledge acquired from other groups across the Cavendish Laboratory.

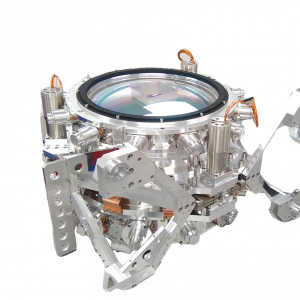

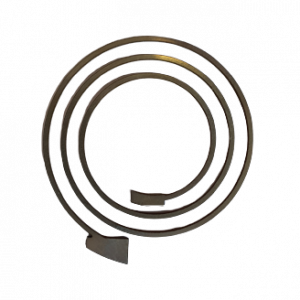

- Using manufacturer’s standard parts or modifying their CAD files, common examples are modifying vacuum component or optical equipment to fit in existing designs or experiments.

We work with most CAD file formats or can advise you on exporting your files so that we can.

Current CAD & CAM packages used: Autodesk Inventor; Autodesk HSM; Autodesk Fusion; Autodesk AutoCAD; OneCNC; Featurwire, the workshop team have experience in several others.

We also offer a top-class welding service!

Here at the workshop welding fabrication can be achieved using state of the art CAD/CAM software and in depth knowledge of fabrication procedures. This can range from fabricating a desk to a mobile cryostat hoist. We also offer the capabilities of welding dissimilar materials such as copper too mild steel and mild steel too stainless steel using silicon bronze filler rod and other specific filler materials.

As well as providing top class welding we also offer brazing and soldering services to help you localise the whole job. On top of that we can also complete sheet metal services.

Please see list below for all welding equipment:

– Miller 300P Tig Welder – Topweld Arc Welder

– Fronius Pulse Mig Welder – Slee Spot Welder

– Rotary Welding Chuck – Castolin Euectic Plasma Cutter

| Mig Welding Thickness: Aluminium = 1.6mm – 12mm Mild Steel = 1.6mm – 25mm Tig Welding Thickness: Aluminium = 1.6mm – 4mm Mild Steel = 1.2mm – 4mm Stainless Steel = 1.2mm – 4mm | Max Folding Dimensions: Aluminium = 1.6mm x 2mtrs Stainless Steel = 1.2mm x 2mtrs Mild Steel = 3mm x 500mm Max Rolling Dimensions: Mild Steel = 1.6mm x 1200mm wide – 1000mm diameter 5mm x 500mm wide – 1000mm diameter |

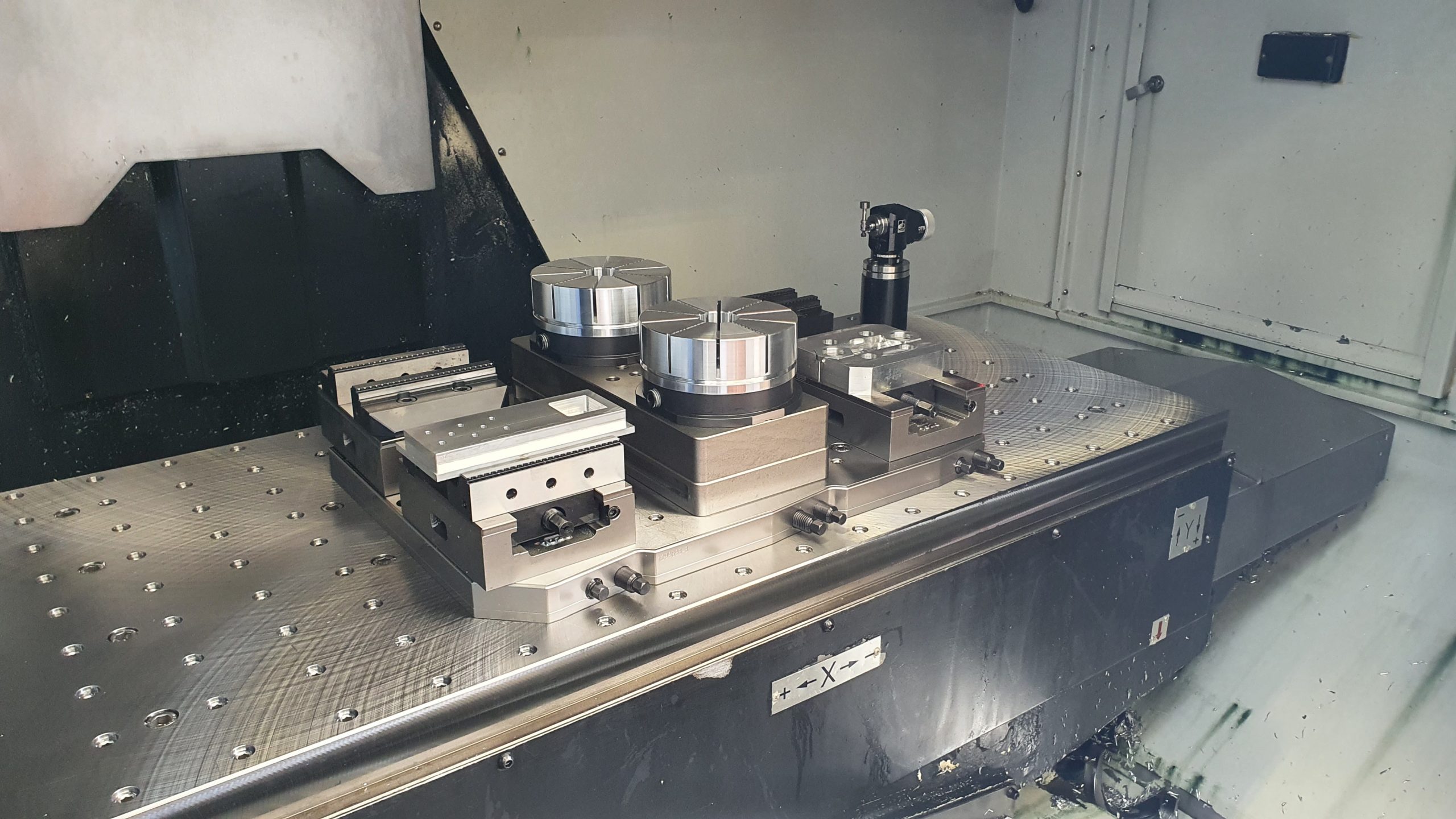

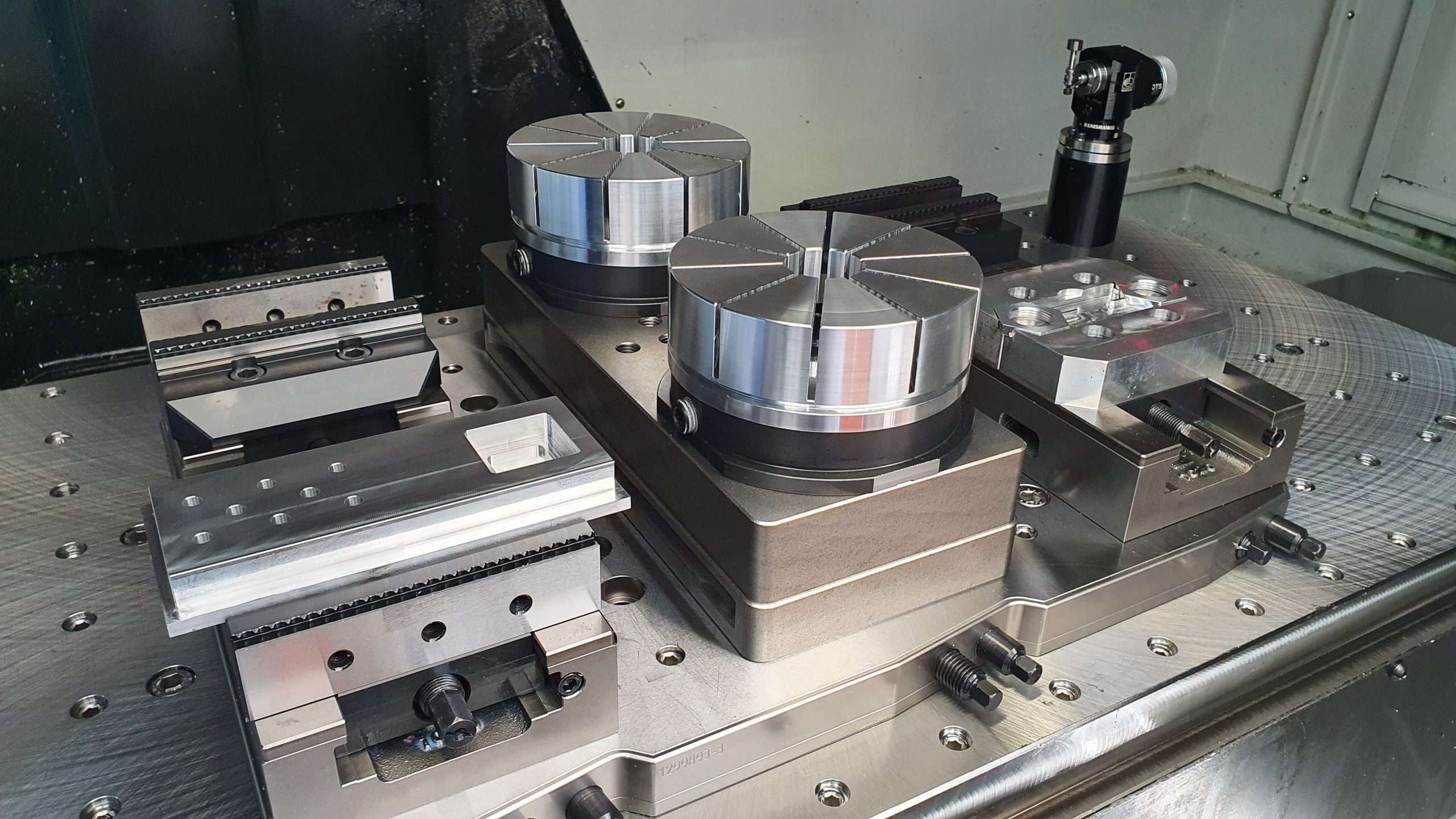

We pride ourselves on our high tolerance work.

CTS has an emphasis on high precision and quality finish. We have our own well equipped inspection department to ensure accuracy and consistency.

For high accuracy measuring we have a Mitutoyo optical shadowgraph. We also have an extensive range of traditional measuring equipment and gauges, including:

- external micrometers

- bore micrometers

- slip gauges

- height gauges

- thread gauges

- plug gauges