FOR SUBCONTRACTING WORK (OUTSIDE THE UNIVERSITY) PLEASE CLICK HERE

Here at Cavendish Technical Services we are here to help you achieve your goals, whether that is creating your next big project or helping guide you to success. We take every request with the upmost care to make sure all your needs are met.

Manufacturing

We have a range of machinery to get your job done. We have 3 axis milling, mill-turn capabilities, wire eroding and a selection of manual machines. All here to get your job done to a high standard.

Design

Priding ourselves in, not only our manufacturing but also our designing capabilities. We have years of experience in mechanical design and are open to work together to bring you what you need!

Fabrication

Not only do we offer machining services but we have the capabilities to carry out tig welding, brazing, soldering and sheet metal work. All to an excellent standard.

Inspection

Cavendish Technical Services has an emphasis on high precision and quality finish. We have our own well equipped inspection department to ensure accuracy and consistency

Training Experience

We also offer first class training in the following areas:

For a full break down of all services offered to university members please click here

Reverse Engineering

By 3D scanning we can reverse-engineer a computer model of an existing part that is either identical to the original or one with specified changes.

About us

Specialising in full product design, development and manufacturing of precision scientific equipment’s for the department’s research requirements. We also provide a service to the rest of the University of Cambridge and to industry.

The workshop team have a wide range of design and machining experience to cover most requests. The variety of jobs undertaken can be small machining items to large complex design and manufacture projects on our CNC mills/lathes and wire-cut EDM. Our range of manual machines can aid quick turnaround jobs.

our team

We have a vast pool of engineering knowledge and are incredibly proud of our highly skilled and experienced local craftsmen. Experts in bespoke and batch work using a wide range of CNC equipment, but we also pride ourselves on still using the basics to help get quick turnarounds on jobs. You can send us a design, or an idea and we shall bring it to life with the upmost precision and care.

subcontracting work

Cavendish Technical Services is based within the University of Cambridge but now have opened doors to the outside world. We have been providing a world class service for over 100 years and can now provide the same service to you. Specialising in full product design, development and manufacturing of precision scientific equipment (currently under the Department of Physics within the University of Cambridge). The variety of jobs undertaken can be small machining items to large complex design and manufacture projects on our CNC mills/lathes and wire-cut EDM.

contact

For any queries please visit our BOOK IN REQUEST page. (You will need to login with your CRSID)

Check out our work

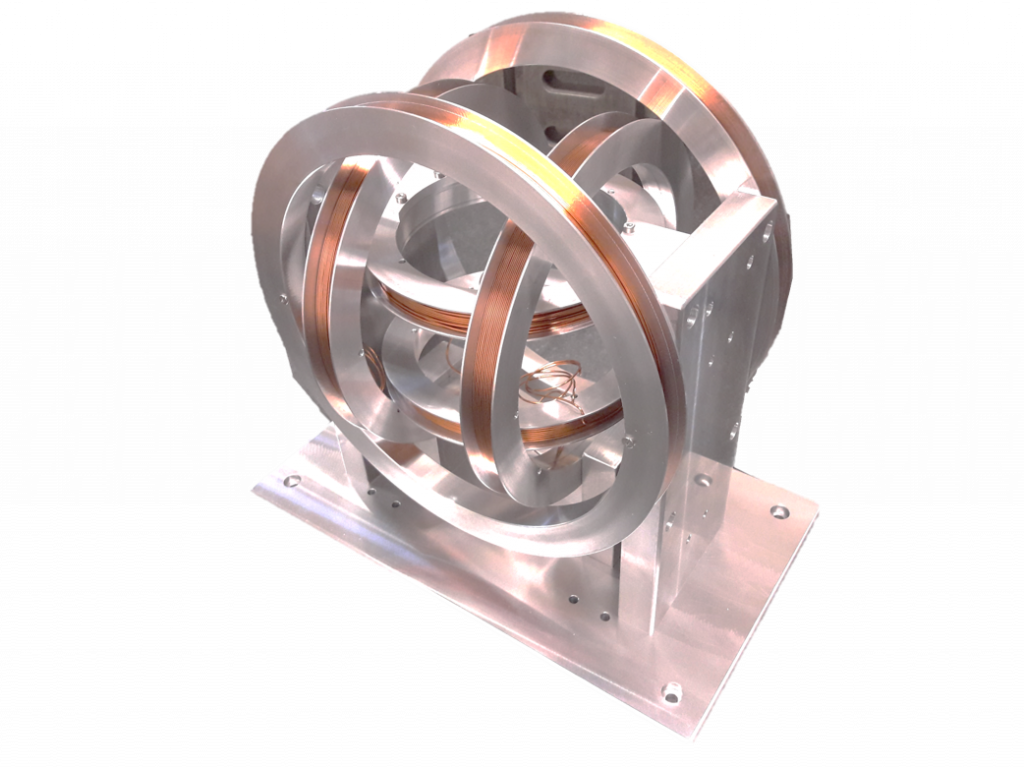

Helmholtz Coil

This Helmholtz coil was manufactured and assembled at Cavendish Laboratory workshop. In 1873 James Clark Maxwell helped push the design for the Helmholtz coil stating that “adding a third larger-diameter coil located midway between the two Helmholtz coils with the coil distance increased from coil radius R to √3R can reduce the variance of the field on the axis to zero up to the sixth derivative of position”.

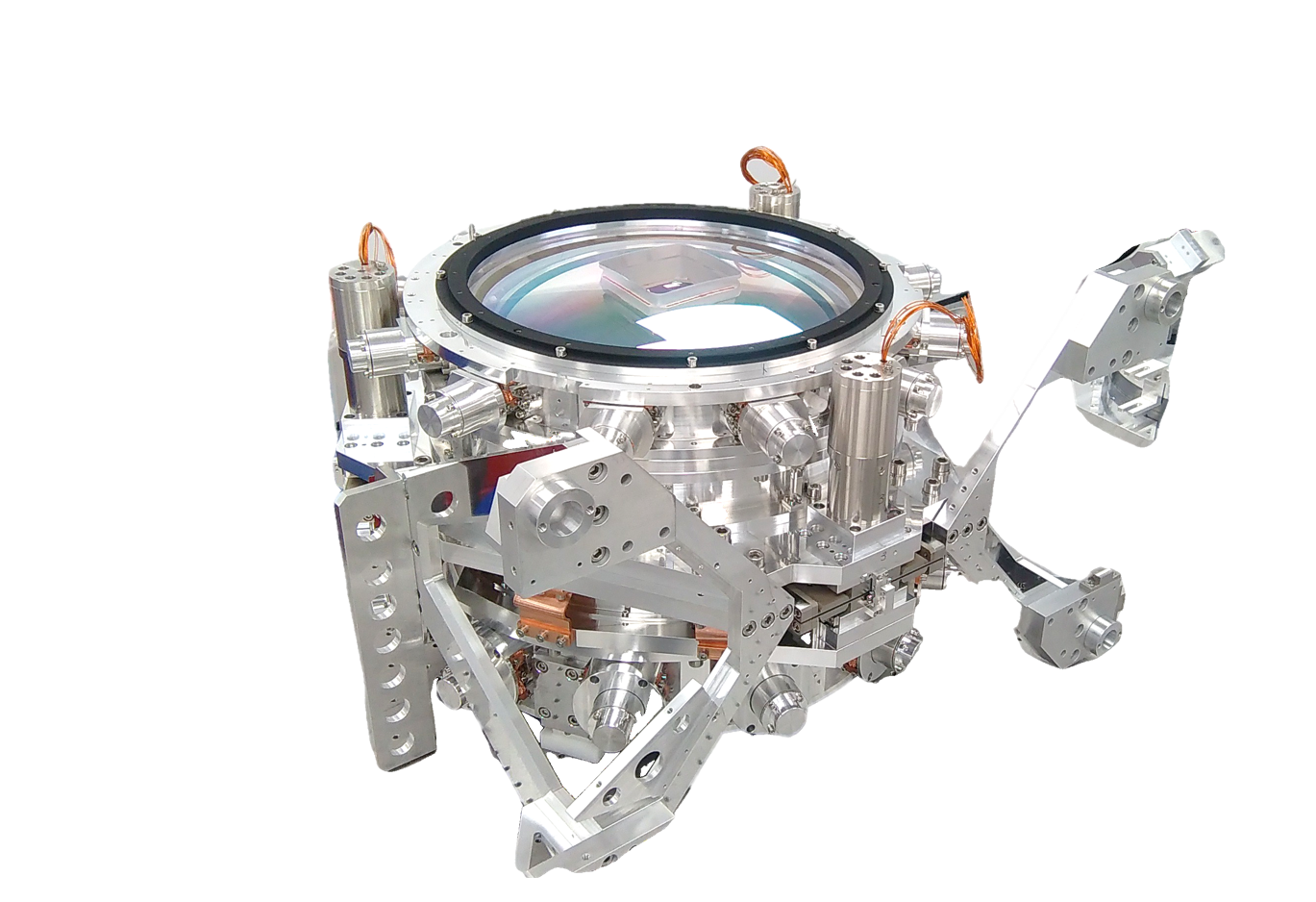

Moons Project

Cambridge is responsible for designing the optomechanics and assembling, aligning and testing the six cameras of the spectrograph. The first set of optics for the first camera have been delivered and mounted in their housing.

FOR SUBCONTRACTING WORK (OUTSIDE THE UNIVERSITY) PLEASE CLICK HERE